I spent Saturday cleaning out the garage. Pulled everything out and hosed down the floor to remove a lot of the dust from paint removal. Then I moped the floor and dusted off a bunch of stuff. I also put the bed on rollers so I could move it around easily.

I pushed the truck out and winched it back in using the 4 wheeler. Once in I got in front with the 4 wheeler and winched it up on the ramps. It would have been nice if my water pump would have came in before hand, I could have just drove it around.

Today (Sunday) I started the trans removal. First I disconnected the drive shaft from the rear and put plastic ties on to hold the caps from falling off. I did not want to loose the needle bearings!

Then on to the front ... 4 nuts with washers and it's off.

Then I disconnected the emergency brake lever and moved it back out of the way.

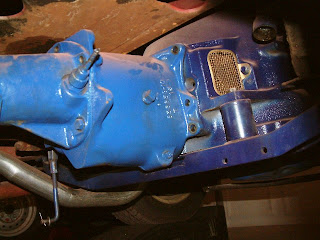

Took the exhaust loose from the manifold. What it did not drop down??!! The muffler shop had welded a piece of round stock from one pipe to the next so that they would only have to use one hanger ... crap. I took out the grinder with a cut off disc and fixed that real quick! I then pushed the exhaust to one side so I could drop the trans straight down.

Then I took the shift lever off and removed the bracket holding it on. also disconnected the linkage and the return spring. Removed the 5 bolts holding the trans to the bell housing.

OK, now the fun stuff ... I knew the trans was not extremely heavy but I also knew that I would not be able to get under it for leverage. In my mind when I pulled it out it would drop down fast and the shaft would smack the cross member, slide off and crash to the floor possibly breaking something to include my hands/fingers. So I needed some added safety.

I ran a strap with hooks around the trans and fed the ends up through the floor where the shift lever sits and attached a ratchet strap to that. I ran the other end out the window and hooked it under the running board. This way I would only have to handle one end and the strap would support the other. The pictures show it all tight, but I actually left quite a bit of slack so it would have room to drop down and back. I also took one of the furniture dollies I was using for the bed and placed it under the trans so that I would not have to let it down as far and I could just roll it out.

Rolling it out was a bit of a challenge since it sat a bit too high to come out the side. I ended up having to roll it straight out the back and that was still a bit tricky!

Once out, I crawled back under the truck and removed the throw out bearing. It does sound rather bad when you shake or turn it. I put the collar in my vice with the bearing laying flush on top. Took a large socket and mallet and taped the collar away from the bearing, seperating the two. Much easier than I thought it would be!

I still have to remove the pressure plate assembly to get to the clutch disc so I can measure it to see if I need the 10 inch or 11 inch. 90 percent of the 55s came with the 10 but since my engine has the 4 barrel carb I could fall into the 10 percent of high performance engines that carried the 11 inch ... I kinda hope I do have the 11. I am still debating on the pressure plate assembly ... it has some wear but I am not sure how much is too much ... These next pictures are from when i had the engine out in Virginia ... man I wish I would have measured the disc then!!

To be continued .....

No comments:

Post a Comment