Thursday, September 30, 2010

Wednesday, September 29, 2010

Transmission stuff

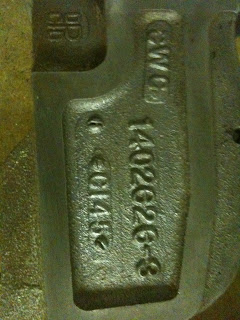

Well I got the trans all cleaned up and ready for paint. I am starting to think it is not a Borg Warner and the the T 16 is just a coincidence. I will have to look into this some more! I will be recording all of the cast numbers and get pictures so I can match this up to something.

So if I wanted to buy a clutch plate and throw out bearing, would I look for one for a the 55 Plymouth engine or the unknown transmission?

I also found the source of the slop in the shifter and I think I can remedy this pretty easily. More on that later.

So if I wanted to buy a clutch plate and throw out bearing, would I look for one for a the 55 Plymouth engine or the unknown transmission?

I also found the source of the slop in the shifter and I think I can remedy this pretty easily. More on that later.

Back in Business

In VA working on the truck again! I'm expecting to get the gasket set today or tomorrow. I'm crossing my fingers that it is the correct set! Yesterday I power washed the intake, trans, trans cross member and bell housing. Then I pushed the truck outside and did it top and bottom.

After power washing the trans I found a hairline crack in the case near the top left bolt hole. I do not think this will cause any problems and I am going to leave it for now. I plan on upgrading to a 4 speed in the future.

Once my gasket set comes in I will be able to replace the main rear seal and put the engine back together. At that point I will be able to finish cleaning the block and paint it. I'm still trying to decide on an engine color. I'm leaning towards Mopar gold or Ford Blue.

More tonight!

After power washing the trans I found a hairline crack in the case near the top left bolt hole. I do not think this will cause any problems and I am going to leave it for now. I plan on upgrading to a 4 speed in the future.

Once my gasket set comes in I will be able to replace the main rear seal and put the engine back together. At that point I will be able to finish cleaning the block and paint it. I'm still trying to decide on an engine color. I'm leaning towards Mopar gold or Ford Blue.

More tonight!

Thursday, September 16, 2010

OH BTW

By The Way ... the truck now has a Georgia Tag! Maybe I'll drive it home LOL ... not that brave yet!

Idle time

Nope not the engine idle LOL ... I spent some time searching for information about the transmission. It's a Borg Warner T-16 out of a 40s-50s Mopar. My guess is it was in a Plymouth as well as the engine --- 1955 Plaza.

I got the information from the jalopyjournel aka H.A.M.B. (Hokey Ass Message Board) website .... great resource for all things "Traditional Rods"

GO HERE

Here was the the reply to my question about the trans and the loose shift lever:

See the full thread HERE.

So another major part will be needed at some point. The trans will work as is for the time being, but I will want something different later on.

Every little fix seems to turn into a big one ...new trans = New mount solution, new mount for the emergency brake, possibly different drive shaft end. And thinking about the transmission has me looking at the rear. Without looking at it , is it too wide? If i put a narrow white wall on the rear would it sit too far out from the bed for a factory sized fender? Hmmm probably ... new fender, new rear and all associated with changing it out ... brakes hubs lines etc.

Just random thoughts ... the good thing is I don't have to do it all at once ... the current set up should work until I have some extra cash to change it.

I got the information from the jalopyjournel aka H.A.M.B. (Hokey Ass Message Board) website .... great resource for all things "Traditional Rods"

GO HERE

Here was the the reply to my question about the trans and the loose shift lever:

"Its a mopar trans from the late 40's - early 50's. It was originally set up as a column shift, so I am guessing the homade floor shift mechanism is probably causing the free play. I would probably redesign the shifter to work correctly, go back to a column shift, or ditch that trans all together and go with a later mopar overdrive trans with a floor shift or a t-5 ."

See the full thread HERE.

So another major part will be needed at some point. The trans will work as is for the time being, but I will want something different later on.

Every little fix seems to turn into a big one ...new trans = New mount solution, new mount for the emergency brake, possibly different drive shaft end. And thinking about the transmission has me looking at the rear. Without looking at it , is it too wide? If i put a narrow white wall on the rear would it sit too far out from the bed for a factory sized fender? Hmmm probably ... new fender, new rear and all associated with changing it out ... brakes hubs lines etc.

Just random thoughts ... the good thing is I don't have to do it all at once ... the current set up should work until I have some extra cash to change it.

Thursday, September 9, 2010

Home for a few week ....

Had to go back to Georgia for a few weeks. Hopefully by the time I go back the gaskets and the manifold will be there waiting!

Tuesday, September 7, 2010

Dropped off my heads ...

Dropped the heads of at the machine shop .... 5 studs to remove and 3 busted studs, crossing my fingers it does not cost too much. Glad that's dealt with!

Monday, September 6, 2010

Off with the heads ....

Got home this evening and removed the intake manifold, alternator. and the heads. No problems. I did find a temp sensor a wire connector, 2 nuts and a washer along with a bunch of gunk on the top line of the heads where the heads meat the engine! I will call around tomorrow and get some prices on removing the remaining studs and the 3 broken studs.

Now it will be easier for me to finish cleaning the block for paint.

Your probably wondering why I do not go ahead and rebuild the engine and port polish etc the heads? Money and lack of. So I will have to make due with what I have for now and worry about that another time.

I still need to remove the flange bolts from the other manifold, and prep the firewall for paint before the engine goes back in. So much to do so little time :o)

Now it will be easier for me to finish cleaning the block for paint.

Your probably wondering why I do not go ahead and rebuild the engine and port polish etc the heads? Money and lack of. So I will have to make due with what I have for now and worry about that another time.

I still need to remove the flange bolts from the other manifold, and prep the firewall for paint before the engine goes back in. So much to do so little time :o)

| ||

| Off with the intake & Alternator ..... |

| |

| Off with the heads .... |

|

| Bolts etc .... |

|

| Not much left ... man those pistons are dirty! |

Sunday, September 5, 2010

Broken Manifold bolts ... been there done that!

Ok so this morning I went to the local Sears and picked up a punch, easy out set, and a reversed drill extractor set. Punched the bolt, drilled a pilot hole then inserted and drilled the extractor in. Once it caught it snapped. Removed that and inserted the easy out. After applying very little pressure it too broke. Used the punch to mark a starting point to try and drill out the easy out and flattened the tip on the punch!

Took all three back to Sears and got my 60 bucks back.

Next chance I get I will start tearing down the engine to get the heads off for the machine shop.

At least I tried :O(

Took all three back to Sears and got my 60 bucks back.

Next chance I get I will start tearing down the engine to get the heads off for the machine shop.

At least I tried :O(

September 04: [Delayed Post] Getting there .....

Started Saturday [Sept 4th] morning scraping and cleaning the block. This is a very slow process but using a wire brush on the air drill helps tremendously! After about an hour, my sister's neighbor walked up carrying an engine stand! Just what I needed.

So, I removed the transmission and the bell housing, installed the engine onto the stand and disconnected the hoist ... life is good. Back to the cleaning process. I spent the better part of the day cleaning on it. I stopped mid evening and got the garage cleaned up. I now have a fresh canvas to dirty up tomorrow :O)

The exhaust manifold should have been taken off the donor car Saturday! I hope the gentleman was able to do it with no hang ups. I would understand if he did not get to it being it is the Holiday weekend. Crossing my fingers just in case. Still no big hurry since the gasket set has at least two weeks before arriving. Hot Heads will wait to place the order with his weekly order to save me the special shipping cost from CA to NC. Once it arrives in NC it comes to me here in VA. I wont be here :O( I have to go home sometime LOL I will be heading home towards the end of this coming week.

I think today [Sunday] I will see if I can find a reverse drill bit and give one of the manifold bolts a try. The worst that can happen is a trip to the machine shop witch is what I was planning anyway.

While I'm thinking of it I want to replace the freeze plugs while I have the engine out. Does anyone know if these are pretty much all the same standard size or is this going to be a treasure hunt? Also not the copper tube on the engine pic above that was cut and pinched off .... are the plugs to replace this fairly standard as well? I will look into this later. Another reminder for me is to research what is causing play in the shift lever and a possible fix for it. I am sure I would get use to hitting the gears but I would rather not have to.

Hope everyone had a fun holiday weekend!

So, I removed the transmission and the bell housing, installed the engine onto the stand and disconnected the hoist ... life is good. Back to the cleaning process. I spent the better part of the day cleaning on it. I stopped mid evening and got the garage cleaned up. I now have a fresh canvas to dirty up tomorrow :O)

The exhaust manifold should have been taken off the donor car Saturday! I hope the gentleman was able to do it with no hang ups. I would understand if he did not get to it being it is the Holiday weekend. Crossing my fingers just in case. Still no big hurry since the gasket set has at least two weeks before arriving. Hot Heads will wait to place the order with his weekly order to save me the special shipping cost from CA to NC. Once it arrives in NC it comes to me here in VA. I wont be here :O( I have to go home sometime LOL I will be heading home towards the end of this coming week.

I think today [Sunday] I will see if I can find a reverse drill bit and give one of the manifold bolts a try. The worst that can happen is a trip to the machine shop witch is what I was planning anyway.

|

| Getting there .... |

| ||

| Trans too .... |

Hope everyone had a fun holiday weekend!

Thursday, September 2, 2010

Dirty Day

I went last night to get the engine gasket set I ordered from Advance Auto. It came in as promised .... wrong one. It came as a set for a small block Chevy. So I returned it and went back home empty handed. Spent a little time scraping on the engine.

A guy came and was going to attempt to remove the broken manifold studs, but once he looked at it he decided he did not want to take the chance of messing something up and decided not to do it. I am seriously thinking of pulling the heads and taking them to a machine shop.

This morning I called Hot Heads out of North Carolina an ordered the correct gasket set, it should be here in a couple of weeks.

I removed the passenger side manifold. It came off just fine. To sum it up I have an old sheared manifold bolt in the passenger side head and 2 that I broke loading in the drivers side head.

I then removed the oil pan and spent the rest of the evening cleaning that up. I found a brass patch under all of that caked on oil and a few dents. I filled the pan with water and checked for leaks ... remember the pan was cut and made shallow at some point in it's life ... no leaks that I could find. I suspect an old pan gasket and rear seal were the cause of the oil leak I was seeing. The pan gasket was pretty brittle.

Here are a few pictures from today:

I wont have much time for the project tomorrow. I will post any new information as soon as I can. I am still trying to locate an engine stand in case I decide to remove the heads. I have a line on two, just waiting for a call back on one and if that falls through I have someone offer one that currently has an engine on it, but he said I could use it.

A guy came and was going to attempt to remove the broken manifold studs, but once he looked at it he decided he did not want to take the chance of messing something up and decided not to do it. I am seriously thinking of pulling the heads and taking them to a machine shop.

This morning I called Hot Heads out of North Carolina an ordered the correct gasket set, it should be here in a couple of weeks.

I removed the passenger side manifold. It came off just fine. To sum it up I have an old sheared manifold bolt in the passenger side head and 2 that I broke loading in the drivers side head.

I then removed the oil pan and spent the rest of the evening cleaning that up. I found a brass patch under all of that caked on oil and a few dents. I filled the pan with water and checked for leaks ... remember the pan was cut and made shallow at some point in it's life ... no leaks that I could find. I suspect an old pan gasket and rear seal were the cause of the oil leak I was seeing. The pan gasket was pretty brittle.

Here are a few pictures from today:

| ||

| Oil pan after clean up. Note the brass patch. |

| ||

| The bolts I sheared off loading the truck. |

| ||

| The sheared bolt already there. |

| ||

| Normal for Hemi |

| ||

| Engine ID |

| ||

| Trans ID Can anyone identify the transmission, it's a 3 speed. |

Subscribe to:

Posts (Atom)